News

The CORE news hub

CORE Group at the 2025 Beyond Expo

Author: Alexandros Patrikios

14th April 2025

Beyond Expo took place last week, and our team couldn’t miss out.

It’s our third time joining the expo, and the first time it takes place in Athens. Our team was there to showcase the latest demos from our Horizon projects, as well as the COREbeat end-to-end predictive maintenance platform.

The CORE Group booth

Throughout the three-day event, we had the pleasure of engaging with many attendees stopping by our booth.

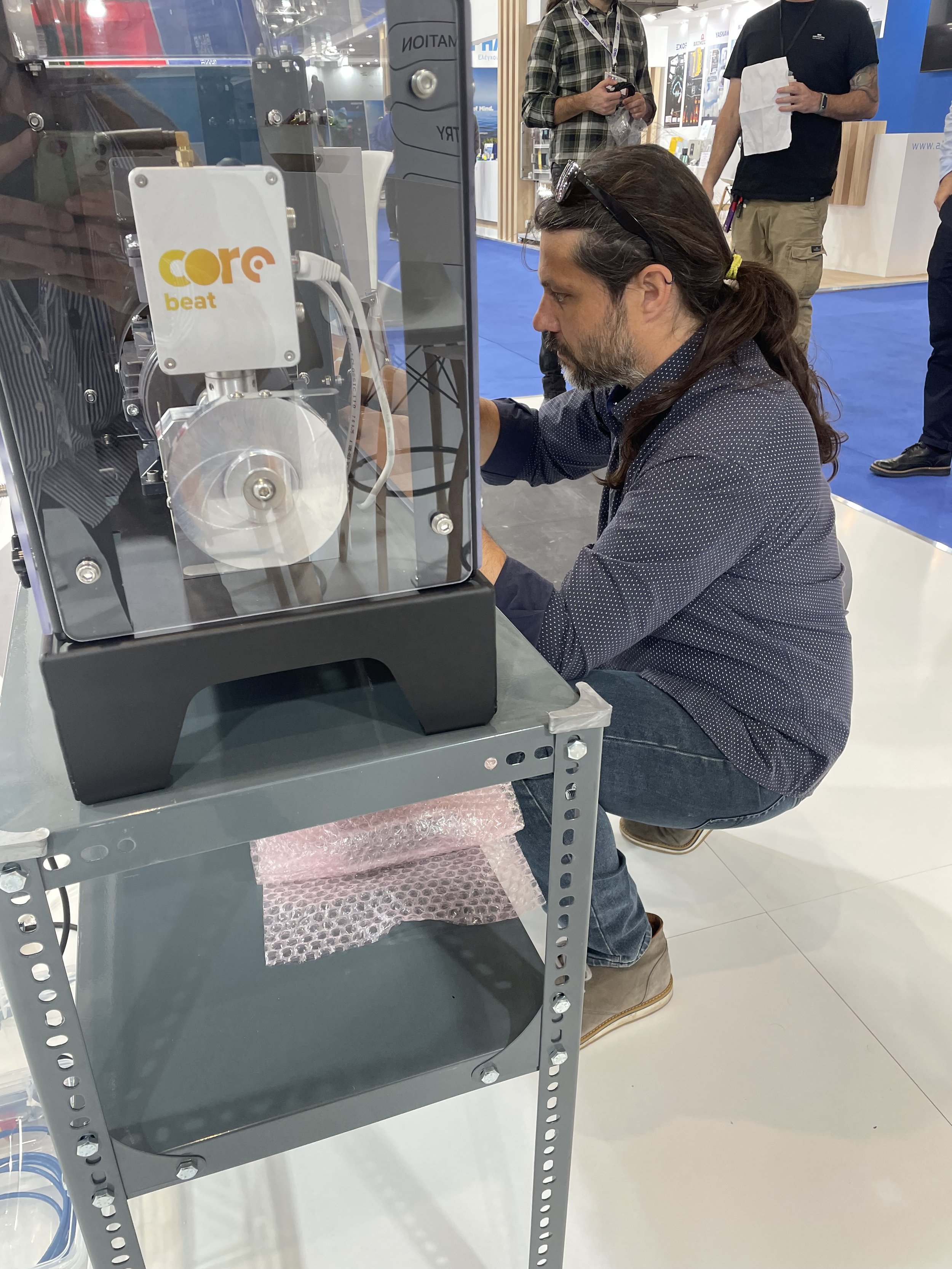

The expo was an interesting mix of industry veterans and AI enthusiasts, all of whom were very excited to see our Predictive Maintenance platform, COREbeat, in action. Our showcase included a motor connected to a beatBox, COREbeat’s hardware component, and visitors were allowed to push a nail in the machine and watch COREbeat’s UI platform spot the malfunction in near-real time. You can watch a short version of our COREbeat demo here.

Visitors also got to learn more about our Research & Innovation initiatives through the CORE Innovation Centre, with two live demonstrations of our most recent demos:

FAIRE, which is a cutting-edge solution that combines AI, edge computing, and federated learning to address critical challenges in industrial operations. FAIRE was developed through our participation in the MODUL4R and RE4DY EU projects. You can watch a short version of our demonstration here.

Smart Manufacturing Lines, a demo of a 3D Simulation-driven optimisation approach, testing different scenarios for smart manufacturing lines. This demo was developed in partnership with SSF, our Twin4Twin project partners, and Visual Components, our visualisation partner in the MODUL4R project.

Apart from our live demonstration, we also showcased the ELEXIA, DACAPO, and TRINEFLEX, all of which focus on energy optimisation across different industries.

Our booth was designed and constructed by the amazing team at Level Up events and exhibitions.

Industry Panel Discussions

Our managing partners, Dr. Nikos Kyriakoulis and Stefanos Kokkorikos, were invited to participate in two separate panel discussions, discussing the latest developments in machine learning and AI.

Stefanos Kokkorikos took part in a panel discussion hosted by HETiA, talking about on the opportunities offered by edge computing technologies, as showcased by our Horizon EU projects participating in the expo.

Nikos Kyriakoulis participated in the main conference of the event, talking about the AI boom and how SIRI can help manufacturers evaluate their Industry 4.0 readiness. You can watch the discussion in the video below.

As part of our participation in the expo, Dr. Nikos Kyriakoulis was also invited for an interview on CORE Group and its initiatives. You can watch the video below.

Stay in touch

A big big thank you to everyone who took the time to stop by our booth and say hi!

We look forward to staying in touch and collaborating.

See you all soon!

CORE Group at the 2025 Smart Factory Conference

Author: Alexandros Patrikios

March 27th 2025

Our team sponsored this year’s Smart Factory Conference, which took place earlier this week.

Dr. Nikos Kyriakoulis, CORE Group Co-Founder and Managing Partner, was invited as a speaker, to talk about the SIRI assessment tool and how it can help manufacturers navigate the Industry 4.0 landscape.

The first step towards Industry 4.0 success

Dr. Nikos Kyriakoulis, Co-Founder and Managing Partner at CORE Group, delivered an intriguing presentation, talking about potential pathways towards Industry 4.0 integration. He presented SIRI, the digital maturity assessment tool that helps prioritise new Industry 4.0 initiatives and systematically re‑validate existing projects.

You can learn more about SIRI here, and you can watch the full presentation below.

The CORE Group showcase

Conference attendees got to take a look at COREbeat, our end-to-end Predictive Maintenance solution. You can find out more information about COREbeat here.

We also got to spotlight some of our key Horizon EU projects, raising awareness about the StreamSTEP and DaCapo projects.

StreamSTEP is a newly-launched project, which aims to streamline the optimisation of Sustainable Thermal Energy Systems and prototype new technologies in process industries.

The DaCapo project, already on its third year, aims at the creation of human-centric digital tools and services for improving the adoption of Circular Economy strategies along both manufacturing value chains and products lifecycle.

Stay in touch

A big thank you to the conference organisers. See you all at the next event!

Two white papers published by our Innovation team

Author: Ioannis Batas

March 20th 2025

At CORE Innovation Days, held earlier this year, our Innovation Department published two white papers: "Our Innovation Management Methodology for EC-funded Projects" and "Factory of the Future: What’s Happening, What’s Evolving, and What’s Next."

The two white papers were distributed to attendees, offering valuable insights into our innovation management methodology and the transformative potential of Industry 4.0.

White Paper #1: "Our Innovation Management Methodology for EC-funded Projects"

In the dynamic landscape of EU-funded research, turning innovative concepts into tangible solutions requires a strategic approach. In the first white paper, we present our Innovation Management methodology, which unfolds through a four-phase exploitation strategy designed to help researchers and consortium partners navigate the entire process. From identifying project Key Exploitable Results (KERs) to developing market roadmaps, our methodology ensures that results are protected through Intellectual Property Rights (IPR) and strategically positioned for market adoption.

Our Innovation Management methodology also features the CORE Exploitation Canvas, a tool we designed to streamline the market entry of KERs from EU-funded projects. The canvas guides teams through 10 key blocks: identifying partners and IP ownership, selecting IPR protection, analyzing the target market, addressing barriers, assessing broader impact, evaluating the State of the Art and Unique Selling Points, outlining exploitation routes, setting actions and milestones, and identifying costs and revenue streams. By simplifying complex innovation processes, the CORE Exploitation Canvas helps teams align outputs with market needs, accelerate adoption, and create sustainable impact.

You can download the white paper here.

White Paper #2: "Factory of the Future: What’s Happening, What’s Evolving, and What’s Next"

Industry 4.0 is revolutionising manufacturing, presenting both opportunities and challenges for companies. Our second paper explores the transformative potential of smart factories enabled by AI, IoT, and other advanced technologies. The global Industry 4.0 market is experiencing explosive growth, projected to reach €511 billion by 2032, driven by the shift towards scalable, automated, and interconnected production systems.

This white paper analyses key technologies shaping the future of manufacturing, from AI and IoT to robotics and additive manufacturing, while addressing the barriers companies should mitigate. It highlights critical issues like workforce upskilling, cybersecurity risks, and the integration of legacy systems, offering practical strategies to navigate these challenges. By bridging current capabilities with future possibilities, this paper serves as a guide for manufacturers looking to embrace digital transformation and secure long-term competitiveness in a rapidly evolving market.

Our insights for this second paper were further enriched by our involvement in leading the exploitation management activities of the MODUL4R and M4ESTRO projects.

You can download the white paper here.

White papers now available online

At CORE Group, we believe that knowledge sharing is essential for driving technological progress and empowering innovators to transform ideas into impactful solutions.

If you missed the event or want to explore further, both white papers are now accessible. Learn how CORE Innovation is shaping the future of research exploitation and innovation management.

For more information, don't hesitate to reach out to our Innovation Department.

FAIRE: Federated Artificial Intelligence for Remaining useful life Edge analytics

Revolutionising Industrial Operations with FAIRE: Federated AI for Predictive Maintenance

Author: Konstantina Tsioli, Pavlos Stavrou

February 20th 2025

At CORE Innovation Days in January, CORE unveiled a groundbreaking demonstration of FAIRE (Federated Artificial Intelligence for Remaining Useful Life Edge Analytics), a cutting-edge solution that combines AI, edge computing, and federated learning to address critical challenges in industrial operations.

This innovative approach not only enhances operational efficiency but also ensures data privacy and scalability, making it a game-changer for industries like manufacturing, energy, and pharmaceutical.

What is FAIRE

FAIRE is a ground-breaking solution based on the MODUL4R and RE4DY EU projects. FAIRE is a federated AI solution designed to optimise industrial processes by leveraging edge computing and federated learning.

It enables real-time data processing and predictive analytics, while keeping sensitive data secure and on-premise. FAIRE showcased how it can be applied to predictive maintenance for CNC machines, but its applications extend far beyond this use case.

Key FAIRE Features

Edge Computing: This solution utilises edge devices deployed directly on the shop floor to collect and process data locally. This reduces latency, minimises bandwidth usage, and ensures real-time insights without relying on constant cloud connectivity.

In the demo, two edge devices were connected to CNC machines, collecting data relevant to tool wear and predicting the Remaining Useful Life (RUL) of milling tools.

Remaining Useful Life (RUL): is a predictive tool that estimates the time left before a machine or component fails or requires maintenance, based on real-time data and historical performance patterns. In the context of FAIRE, the RUL model predicts tool wear in CNC machines, enabling proactive maintenance and reducing downtime while ensuring data privacy and security.

Federated Learning: FAIRE employs federated learning to enable collaborative intelligence across multiple machines or factories. Instead of sharing raw data, only model parameters (e.g., insights and updates) are sent to a central server, ensuring data privacy and compliance with regulations like GDPR. This approach allows machines to "learn" from each other, improving prediction accuracy and operational efficiency without compromising sensitive information.

Data Privacy and Security: By keeping data on-premise and sharing only model updates, FAIRE ensures that proprietary information remains secure. This is particularly important for industries with strict data protection requirements.

Scalability and Flexibility: FAIRE’s architecture is designed to scale effortlessly. As new machines or edge devices are added to the network, they can seamlessly integrate into the federated learning ecosystem, enhancing the system’s overall intelligence and resilience.

Predictive Maintenance for CNC Machines

The demonstration of FAIRE solution focuses on a real life application: predictive maintenance for CNC machines. Here’s how it worked:

Data Collection: Two edge devices were connected to two CNC machines, collecting real-time data on tool wear and machine performance using industrial protocols like OPC-UA and MQTT.

Local Processing: The edge devices preprocessed the data locally, running AI models to detect anomalies and predict RUL. Results were displayed on monitors, providing operators with actionable insights.

Federated Learning: Model updates from each edge device were aggregated to a central server to update the global model. The updated model was then sent back to the edge devices, enhancing their predictive accuracy.

Real-Time Insights: Operators then could monitor tool wear and RUL in real time, enabling proactive maintenance and reducing downtime.

The benefits of FAIRE

FAIRE offers numerous benefits for industrial operations:

Smarter Machines: Continuous learning and adaptation improve machine performance and operational efficiency.

Enhanced Data Privacy: Sensitive data remains on-premise, ensuring compliance with data protection regulations and/or requirements.

Cost Optimisation: Reduced data transmission and proactive maintenance minimise operational costs.

Collaborative Intelligence: Federated learning enables machines to learn from each other, improving model accuracy across the network.

Scalability: The solution can easily scale to include additional machines or factories, making it suitable for large industrial networks.

Application areas

While the demonstration of FAIRE solution involved an example of CNC machines, its capabilities extend to various industries:

Pharmaceutical: In a sector where protecting sensitive and production data is paramount, this solution safeguards data privacy and security.

Automotive: Enhance predictive maintenance for automotive production lines.

Aerospace: Improve the performance and reliability of aircraft components.

Energy and Smart Grids: Monitor and optimise power grid equipment like transformers and substations.

Mining: Optimise the operation of heavy machinery like excavators and drilling equipment.

FAIRE represents a significant leap forward in industrial AI, combining the power of edge computing and federated learning to deliver real-time insights, enhance data privacy, and optimise operations. By addressing critical challenges like unexpected downtime, inefficient data handling, and legacy equipment limitations, FAIRE empowers industries to achieve smarter, safer, and more efficient operations.

Solutions like FAIRE will play a critical role in shaping the future of industrial automation and data-driven decision-making.

Introducing Smart Data Management to Mining Operations

Authors: Konstantina Tsioli, Nikolaos Gevrekis, Konstantinos Plessas

February 13th 2025

The CORE Innovation Centre team has developed a key backend platform for the MASTERMINE project, which aspires to become the go-to ecosystem for mines that envision digitalisation, environmental sustainability, productivity monitoring and public acceptance.

A key module of the MASTERMINE project is Cybermine, which serves as the access point to the physical world managing the field data for all components, connecting the physical and digital world through technologies like IIoT, the cloud, edge computing and machine learning ensuring the smart mine design and predictive maintenance of equipment and vehicles.

Our team has developed a backend platform within the Cybermine module, which seamlessly integrates and manages data from various sources across the mining industry. As a smart data management system, it automates data collection, storage, and access, ensuring flexibility, scalability and efficiency in the use of data.

Here’s a look at the ingredients that make this platform innovative.

An overview of the back-end platform developed by the CORE IC team

Collecting Data from Different Sources

Everything begins with data sources, which can include sensors, devices, or systems in the mining industry that generate information. However, not all data is the same - different sources provide data in different formats, structures, and transmission methods. Some data is received in real-time, while other data arrives in scheduled batches. In some cases, end users may even need to manually upload files. The platform uses a multi-layered storage approach, enabling it to secure and organise data types like real-time updates, historical records, and large files. Tools such as S3 buckets, InfluxDB, and PostgreSQL ensure both speed and reliability.

Making the Data Available to Users

Once stored, the data needs to be easily accessible. This is where the Consumption Layer comes in. This layer allows users to retrieve any data they need, whether it’s raw data straight from the source, processed insights, real-time feeds, or historical records. Through this layer, users can access raw or processed data quickly and efficiently, tailored to their specific needs, such as real-time monitoring or historical analysis.

Innovation: Making Data Collection Smarter

Traditionally, integrating data from different devices and sensors required custom-built services for each type of data source, making the process slow and complicated. The platform developed by our team eliminates this challenge by offering an automated, intelligent system that dynamically adapts to any new data source. Consequently, the effort needed to integrate new data sources is significantly reduced.

Significance for the Mining Industry

Mining operations are known for their harsh conditions, making it challenging to collect and manage data effectively. A platform like the one developed by CORE IC is critical because it simplifies data integration and enables the seamless collection of data from diverse sources, even in environments where traditional methods struggle. Its robust architecture ensures data reliability and accessibility, even in remote or extreme locations.

The ability to interpret data ahead of time is crucial for mining operations, particularly regarding heavy machinery, where real-time insights can prevent breakdowns, enhance maintenance schedules, and ensure operational continuity. By transforming raw data into actionable insights, the platform empowers decision-makers — whether managers, operators, or engineers — to make informed decisions, improving safety, productivity, and efficiency. Ultimately, the platform supports innovation, sustainability, and operational resilience in the demanding context of the modern mining industry.

CORE Innovation Days: Shaping Tomorrow’s Industry, Today

The inaugural Industry 4.0 conference, hosted by CORE Group, was an astounding success.

Author: Alexandros Patrikios

January 23rd 2025

CORE Innovation Days, Greece’s first Industry 4.0 conference, took place last week. The two‑day, invitation‑only conference brought together key global leaders from industry, academia, and policy‑making to showcase new trends, challenges and successes in digital transformation and discuss the future of Industry 4.0.

The event was funded through the CORE Innovation Centre’s participation in Twin4Twin, a project supported by the Horizon EU Widening Work Programme.

The main event | Day 1

The conference opened with remarks from Stefanos Kokkorikos and Dr. Nikos Kyriakoulis, Founders and Managing Partners of CORE Group, welcoming conference attendees and introducing the Twin4Twin project.

Their welcome was followed by greetings from distinguished guests, including Stefan Estermann, Ambassador of Switzerland in Greece; Prof. Konstantinos Karantzalos, Secretary General at the Ministry of Digital Governance; and Michail Dritsas from the Greek Ministry of Economy & Finance, who highlighted the STEP Programme’s potential in advancing Greek and European organisations.

Session A: Digital Transformation in Industry

Session A explored the transformative journey industries are taking to embrace digital innovation throughout their production pipeline, in Greece and abroad.

George Panagiotopoulos (EY) focused on the digital transformation journey of Greek industry, suggesting ways for manufacturers to leverage digital tools to create value sustainably and at scale. Raimund Klein (INCIT) introduced the strategic framework offered by the SIRI tool to Greek audiences. Dr. Dominic Gorecky (SSF) shared some real-world insights from the Swiss model for a smart factory. Dr. Nikos Kyriakoulis concluded the session, introducing CORE Group’s Greek Smart Factory initiative – a platform for manufacturers and tech providers to network, innovate and test before they invest.

Session B: The Present and Future of Industry 4.0

Session B provided a forward‑looking perspective on the technologies driving Industry 4.0 and was moderated by Prof. David Romero (World Manufacturing Foundation). Prof. Romero presented the 2024 World Manufacturing Report, which offers insights on future-proofing manufacturing and was edited by a global team of contributors, including CORE Group’s Dr. Nikos Kyriakoulis. You can read the full report here.

Discussions focused on how businesses can prepare for an uncertain and ever‑evolving future through strategic frameworks and advanced technologies such as artificial intelligence and digital modelling. Prof. Dimitris Kyritsis (University of Oslo) introduced foundational frameworks for connecting digital assets. Dr. John Soldatos (Netcompany) highlighted the transformative potential of generative AI and LLMs in industry. Dr. Foivos Psarommatis (Zerofect) discussed upcoming regulations on DPPs and how they are expected to affect industrial operations. Ignacio Montero Castro (AIMEN) explained how AASs can act as bridges between physical and digital worlds. Dr. Jacopo Cassina (Syxis) explored industrial data spaces as tools for cognitive production. The final speaker for this session, Jarkko Soikkeli (Visual Components) examined the evolution and applications of Digital Twin technologies in productivity optimisation.

Session C: Industry 4.0 Innovation Case Studies

The final session of the day showcased real-world applications of Industry 4.0 applications, highlighting groundbreaking Horizon EU Industry 4.0 projects from CORE Group and its partners in three separate panel discussions.

The first panel, Digital and Green Transition of Manufacturing, moderated by CORE Group’s Dr. Pantelis Papachristou, explored how digital and green technologies are reshaping manufacturing ecosystems, identified challenges and opportunities, and discussed the roles of innovation, data, and AI-collaboration in driving this change. Projects discussed included, among others, MODUL4R, M4ESTRO, and Circular TwAIn. Panel participants included Dr. Dimitris Panopoulos (Suite5), Prof. Paolo Pedrazzoli (TTS), Prof. Pedro Malo (Unparallel), Dr. Niki Kousi (EIT Manufacturing) and Dr. Vicky Panagiotopoulou (LMS).

The second panel, Energy and Sustainability of Processes with Industry 4.0, was moderated by CORE Group’s Valia Iliopoulou and focused on energy‑efficient and sustainable industrial processes, such as the ones introduced in TRINEFLEX. Panel participants included George Tsimiklis (ICCS), Dr. Mario Pichler (SCCH), Anna Domènech Abella (CELSA) and Dr. Hussam Jouhara (Brunel University of London).

The third panel, Digital Transformation of Mines with Industry 4.0, moderated by CORE Group’s Konstantina Tsioli, attempted to address inefficiencies, sustainability issues, and resilience demands in the mining industry, driven by high global demand for raw materials, declining ore grades, and environmental imperatives. Milestone mining projects such as MASTERMINE took center stage. Panel participants included Dr. Antonis Peppas (NTUA), Dr. Jose Ramon Valdés (ITA), Kostas Botsialas (AURORA), Dr. Santiago Cuesta Lopez (ISMC) and Emilios Vazoukis (Terna MAG).

Parallel Demo Sessions

Throughout the conference, attendees got to stop by demos set up by our team, showcasing different Industry 4.0 technology trends. One of our demos showcased COREbeat, our end‑to‑end predictive maintenance platform, which included a motor connected to a beatBox, COREbeat’s hardware component. Visitors were allowed to push a nail in the machine and watch COREbeat’s UI platform spot the malfunction in near‑real time. Another demo showcased a solution for AI application deployment which boasts data acquisition on the edge, AI modes for Remaining Useful Life and Federated Learning for increasing data volume while retaining enhanced data privacy – a combination of technologies used in MODUL4R and RE4DY, two of our Horizon EU projects. The final demo, which our team carried out in collaboration with the Swiss Smart Factory, scenario–based optimisation of an actual manufacturing process for drones, using Digital Twins and 3D visual representation for enhanced explainability.

Proposal Writing Workshops | Day 2

For the second day of the event, participants were invited to proposal writing workshops, aimed at fostering collaboration and building consortia for upcoming Research & Innovation calls. Throughout the day, partners met in groups to explore specific funding opportunities, during focused parallel sessions carried out in CORE Group’s central offices.

These workshops were designed to empower participants with practical insights and strategies for crafting competitive proposals, ensuring alignment with the latest Horizon EU priorities. By facilitating direct interaction and knowledge exchange, CORE Innovation Days is paving the way for innovative partnerships and impactful solutions that address the challenges of tomorrow.

Looking Ahead

The inaugural CORE Innovation Days has set a strong foundation, starting an international dialogue on Industry 4.0 in Greece. By fostering collaboration among global leaders, sparking meaningful discussions on cutting‑edge technologies, and equipping participants with tools for future success, this event has proven to be a transformative milestone.

Beyond showcasing innovations, the first CORE Innovation Days fostered meaningful knowledge exchange, with participants sharing experiences and best practices that highlight the value of collaboration within Industry 4.0.

For more information and updates, you can visit the event’s dedicated website.

Building on this momentum, we look forward to welcoming our community again next year.

Celebrating CORE Group’s 2024

Author: Alexandros Patrikios

December 20th 2024

It’s been a big year for our team, full of outstanding recognitions of our collective efforts, industry events and conferences, and brimming with new initiatives beyond our many Horizon EU projects.

Honestly, it’s been a lot to take in, but here’s the gist of it.

Events

Our team hit the road more than ever this year, with corporate participation in 1 summit, 2 expos, 4 sponsored events and more than 10 conferences!

As we gear up for even more participation to industry events next year - and to organising some of our own – we thank everyone who took the time to visit our booths, engage with our team and suggest collaboration pathways for our teams.

New COREbeat installations

COREbeat’s impact on industry continues to grow! This year, COREbeat was installed at many key Greek industry facilities, including TERNA MAG and EYDAP, as well as Tharsis and HALCOR, through CORE Group’s participation in Horizon EU projects.

Our team also received some praising testimonials from previous installations of COREbeat. COREbeat was successful in assisting Marini Marmi, a 120-year old marble quarry in the north of Italy, in modernising its legacy equipment and machinery, and informing their staff about machinery parts being in critical condition. In EP.AL.ME., a leading Greek manufacturer, COREbeat informed the staff of potential upcoming malfunctions, sparing them from unexpected downtime, delays in the factory’s production pipeline, and substantial losses due to production delays.

As COREbeat’s impact continues to grow, we are always looking for new partners eager to get started on their predictive maintenance journey and revolutionise their industrial facilities. If you are interested, you can reach out to our team through info@core-beat.com and share more information on your needs.

R&D Projects

CORE Group and the CORE Innovation Centre have joined forces with partners across the EU in a total of 16 new Horizon Europe projects. Some of these projects have already launched this year, while others are just getting ready to kick things off!

The new projects bring our total to over 50 research projects, ongoing or completed, and increase our research budget to over 24 million €. We are very excited for these brand new R&I initiatives, a preview of which you can get below, and look forward to working with our partners to transform industry with the power of AI.

As the years closes, we are also looking back at many of our years-long consortia, which have wrapped up activities this year, including Dig_IT, SATO, TEAMING.AI, InComEss and MOSES. It’s been an amazing experience working closely with all our EU partners to deliver radical Industry 4.0 change in key EU industries.

We look forward to a bright future with even more fruitful collaborations.

SIRI Assessors

This year, CORE Group Founders and Managing Partners, Stefanos Kokkorikos & Dr. Nikos Kyriakoulis, were invited by INCIT thanks to the GSF initiative to become certified SIRI assessors.

The Smart Readiness Index (SIRI) is a digital maturity assessment tool that helps systematically re-validate existing Industry 4.0 projects or launch new initiatives. It was developed by industry experts and is recognised by the World Economic Forum as the global standard for Industry 4.0 transformation.

Thanks to this internationally recongised certification, CORE Group is currently the only company in Greece certified to conduct Industry 4.0 readiness assessments with the SIRI tool.

For more information on how to get your Industry 4.0 assessment, you can contact secretary@core-innovation.com.

SIRI is a digital maturity assessment tool that evaluates Industry 4.0 readiness in three levels: process, technology and organisation.

Launch of the Greek Smart Factory

CORE Group’s newest endeavour, the Greek Smart Factory (GSF), was announced this past summer. GSF is envisioned as a platform for manufacturers, tech providers and academia, allowing them to network, innovate, and advance in a real industrial environment.

The official announcement took place during the 5th International Smart Factory Summit in Switzerland, followed by a stakeholder workshop at our central offices in Athens, Greece, attended by key professionals and manufacturing decision-makers from Greece and our global network.

CORE IC has been funded to create GSF thanks to this rich know-how, and through its participation in the Twin4Twin project.

Learn more and find out how you can get involved here.

The Industrial Production & Manufacturing Awards

This year CORE Group had a big first, achieving outstanding recognition at the 2024 Industrial Production & Manufacturing Awards!

Our team took home 4 awards, with the highlight of the evening being CORE Group’s distinction as Leading Provider of the Year. This prestigious honour recognises our team’s continuous commitment to delivering cutting-edge technology and services for Greek Industry.

A big winner of the evening was COREbeat, our end-to-end predictive maintenance platform, which earned two significant awards, including the Silver Award for Best Technology Systems for Prodution, and Gold Award for Best Industrial IoT. COREbeat’s use of advanced Industrial IoT (IIoT) methodologies, machine learning, cloud computing, and edge computing has positioned it as a trusted tool for achieving new levels of operational efficiency, and it’s already being piloted with installations in heavy-duty industries in Greece and abroad, including EP.AL.ME. (part of the Metlen Group), EYDAP, Marini Marmi in Northern Italy, Terna Mag, MAXI, Halcor, and Calpak, among others.

The CORE Innovation Centre (CORE IC), our non-profit research and innovation centre, also got its moment in the spotlight, winning the Silver Award in the Rising Star category. CORE IC is involved in over 50 European research projects funded by the Horizon program, with a global network of more than 300 partners and over €24 million in funding.

Our heartfelt thanks to the organisers and judges for these awards and to our partners who continue to inspire us.

Looking towards the future

As 2024 draws to a close, we are immensely proud of the milestones our amazing team has achieved this year. With even more ambitious plans for 2025, we are ready to build on this year’s momentum and help even more organisations advance on their Industry 4.0 transformation, strengthening our partnerships, and delivering value to manufacturers worldwide.

CORE Group at the 9th Raw Materials Community Dialogue

Author: Alexandros Patrikios

December 3rd 2024

This year’s Greek Raw Materials Community Dialogue, hosted by EIT Raw Materials RIS Hub Greece, took place this November.

CORE Group, as an event sponsor, was there to discuss the future of the raw materials and mining sector, in Greece and abroad.

Accelerating Mining Digital Transformation

Stefanos Kokkorikos, Co-Founder and Managing Partner at CORE Group, was invited to deliver a panel session speech. He took the opportunity to showcase CORE Group’s exemplary work in the sector, through our participation in landmark Horizon EU projects.

Stefanos took attendees through a trip “from Pit to Processing“, explaining what Industry 4.0 transformation entails in the mining sector. He showed how analytics can make exploration smart, how predictive maintenance algorithms can be implemented at the extraction stage, and how Industry 4.0 technology solutions can facilitate the processing stage.

If you didn’t get a chance to join the event, you can download his presentation here.

Poster session

The panels were followed by poster sessions, where attendees got the chance to share more information on their work in the mining sector.

CORE Group attended the event on behalf of the MASTERMINE and DEXPLORE consortiums. The MASTERMINE project aims to become the go‑to ecosystem for mines that envision digitalisation, with a focus on the Industrial Metaverse approach. DEXPLORE is a new venture for our CORE team, which aims to innovate deep‑land critical mineral exploration through a mix of innovative technologies, like advanced earth observation methods and extended reality solutions. You can follow DEXPLORE on LinkedIn - its website is under construction.

Partners from our PRIM‑ROCK consortium were also in attendance. PRIM‑ROCK is a new project which aims to improve the resource efficiency of the calcination and roasting processes through a multifaceted, input to output strategy, comprising advanced pre‑processing techniques and AI‑driven process simulations. PRIM‑ROCK has just had its kick‑off meeting - follow its account on LinkedIn to stay up-to-date.

Stay in touch

A big thanks from the CORE team to the dialogue organisers for a very intriguing day, engaging discussions and an insider look at the Industry 4.0 future of mining.

See you all soon.

CORE Group Recognised as Leading Provider at the 2024 Industrial Production & Manufacturing Awards

Author: Alexandros Patrikios

November 21st 2024

CORE Group has achieved outstanding recognition at the 2024 Industrial Production & Manufacturing Awards, taking home 4 awards, including the title of Leading Provider of the Year. This prestigious honor for CORE Group, along with awards for COREbeat and our CORE Innovation Centre, underscores our team’s ongoing dedication to advancing technology solutions that empower industry leaders in Greece and beyond.

This year’s Industrial Production & Manufacturing Awards took place on Thursday, November 14, and provided an opportunity to celebrate excellence and innovation across the Greek industrial sector. CORE Group, as part of this dynamic community and a key contributor to the industrial transformation in Greece, was nominated in 5 categories in total.

CORE Group recognised as Leading Provider of the Year

The highlight of the evening was CORE Group’s distinction as Leading Provider of the Year, which recognises our continuous commitment to delivering cutting-edge technology and services for Greek Industry.

This is a major acknowledgment for our team of 70 employees and their concentrated efforts to deliver solutions that empower industrial operations and help people, industries and companies fulfil their true potential. We’re honored and look forward to building on this momentum.

Awards for COREbeat

The big winner of the evening was COREbeat, our end-to-end predictive maintenance platform, which earned two significant awards. In the Best Technology Systems for Production category, COREbeat received the Silver Award, identifying it as a cutting-edge technology which helps reshape industrial organisations’ operational models and facilitates their digital transformation journey. COREbeat is already being piloted with installations in heavy-duty industries in Greece and abroad, including EP.AL.ME. (part of the Metlen Group), EYDAP, Marini Marmi in Northern Italy, Terna Mag, MAXI, Halcor, and Calpak, among others.

COREbeat also secured the Gold Award in the Best Industrial IoT category, recognising the strength of a technology grounded in more than a decade of know-how in machine learning and predictive maintenance in manufacturing. COREbeat’s use of advanced Industrial IoT (IIoT) methodologies, machine learning, cloud computing, and edge computing has positioned it as a trusted tool for achieving new levels of operational efficiency.

Award for CORE Innovation Centre

The CORE Innovation Centre (CORE IC), our non-profit research and innovation centre, also got its moment in the spotlight, winning the Silver Award in the Rising Star category. Although CORE IC was founded recently, its impact is already significant, with over 50 European research projects funded by the Horizon program, a global network of more than 300 partners and over €24 million in funding. CORE IC is now the second-ranked private organisation in Greece for Horizon program funding, highlighting its position at the forefront of research and innovation.

Our heartfelt thanks to the organisers and judges for these awards and to our partners who continue to inspire us.

As we look towards the future, CORE Group is excited to develop new partnerships and deliver solutions that help drive progress across even more sectors in Greece.

CORE Group participated in a focus group workshop at HALCOR

Author: Maria Tassi

November 13th 2024

A successful Focus Group Workshop was held on 31st of October 2024 at the HALCOR facilities, in Boeotia, Greece as part of the CARDIMED project.

Participants in the workshop included representatives from CORE Group, ICCS, NTUA, HALCOR employees and managers, as well as regional stakeholders, enabling collaboration and knowledge exchange.

The CARDIMED project

CARDIMED is a project funded by the Horizon Europe Programme focused on boosting Mediterranean climate resilience through widespread adoption of Nature-based Solutions (NBS) across regions and communities.

Our CORE team will develop a cloud-based orchestration middleware for efficient data handling across diverse sources, and also focus our efforts on industrial symbiosis through smart water management in the HALCOR demo site, using digital twin technologies.

The workshop aimed at promoting innovative solutions in industrial manufacturing, conducted in the context of Digital Solutions creation that offer tailored views for visualising information to non-experts, citizens etc., with emphasis on the Demonstration case of Industrial symbiosis through smart water management.

Workshop goals and objectives

The main objective of the workshop was to engage end users to gather feedback and prioritise the requirements, and consequently translate the business requirements of end user, HALCOR, to technical requirements leading to implementation of digital solutions and bringing innovation to the industry.

The workshop was opened by M.Sc. Efstathia Ziata (HALCOR), who presented the CARDIMED project and its objectives. Following her presentation, Dr. Ioannis Meintanis (CORE IC) gave insights on the digital twin solution, which is a replica of a physical asset that simulates its behaviour in a virtual environment, highlighting its role in supporting Water-Industrial Symbiosis within HALCOR's factories.

Dr. Maria Tassi (CORE IC) presented other Digital Solutions implemented as part of the HALCOR demo, such as the Nature-Based Solutions (NBS) definition and scenario-based impact assessment interface, the climate resilience dashboards and data storytelling, the citizen engagement app and intervention content management and the NBS exploitation and transferability support module, highlighting their potential to enhance efficiency and sustainability in operations.

Notable contributors to the round table discussions included M.Sc. Katerina Karagiannopoulou (ICCS) and M.Sc. Nikolaos Gevrekis (CORE IC), who provided valuable perspectives on the digital solutions.

Impact on Industry

The success of the workshop lies in end users’ discussions on the various digital solutions, who provided valuable feedback and prioritised user requirements to be integrated in the Digital Twin solution. Their insights will be critical in shaping a final product that effectively addresses the evolving demands of the industry.

These innovations are set to significantly impact the manufacturing industry, by enhancing resource efficiency and sustainability. They will help optimise water usage and promote resource reuse across interconnected processes, leading to cost savings and reduced environmental footprints.

CORE Group’s collaboration with HALCOR

These technological advances will enable HALCOR to optimise its manufacturing processes and resource management in real time, resulting in improved operational efficiency, significant cost savings and reduced water consumption. By adopting sustainable practices, HALCOR can strengthen its reputation as an industry leader in sustainability and appeal to environmentally conscious stakeholders.

HALCOR is a strategic partner for CORE Group, with a collaboration extending across three more Horizon Europe projects, TRINEFLEX, StreamSTEP and THESEUS. As part of the TRINEFLEX project, HALCOR has integrated COREbeat, CORE Group’s all-in-one Predictive Maintenance Platform at its Copper Tubes Plant facility in Boeotia. COREbeat’s asset monitoring capabilities are helping HALCOR acquire deep monitoring insights and increase the availability, flexibility, efficiency and reliability of their equipment.

COREbeat, our all-in-one Predictive Maintenance solution, relies on the beatBox hardware component, pictured here.

CORE Group at the 17th Maintenance Forum

Author: Alexandros Patrikios

October 31st 2024

This year’s Maintenance Forum took place earlier this month.

CORE Group, event sponsor and longtime exhibitor, was there to discuss the future of predictive maintenance.

Expanding Predictive Maintenance with COREbeat

Dr. Nikos Kyriakoulis, Co-Founder and Managing Partner at CORE Group, was invited to deliver a presentation, showcasing how COREbeat’s cutting-edge features can help manufacturers go beyond maintenance to see the bigger picture. COREbeat’s health monitoring feature can be used as a compass for data-driven decision making, in areas such as product quality prediction, overall power consumption, and the optimisation of production processes.

You can watch his full presentation below.

The CORE Group showcase

Conference attendees got to take a look at COREbeat, our end-to-end Predictive Maintenance solution. Stopping by our booth, visitors got to interact with beatBox, COREbeat’s hardware component, as well as COREbeat’s highly intuitive UI platform. You can find out more information about COREbeat here.

We also got to offer some insights into our ground-breaking research and innovation of the CORE Innovation Centre, through Trineflex, a key project transforming energy intensive process industries. Through this project, COREbeat has been installed at the EYDAP wastewater treatment plant in the region of Attica. You can find out more about this pilot installation here.

Stay in touch

A big thanks from the CORE team to the conference organisers for a very intriguing day and an insider look at the future of maintenance.

See you all soon.

CORE Group awarded 9 new Horizon EU projects

Author: CORE Innovation Centre

10th September 2024

CORE Group and CORE Innovation Centre are joining forces with partners across the EU in a total of 9 new Horizon Europe projects. Our team is responsible for 4 of these successful research proposals.

The new projects bring our total to over 50 research projects, ongoing or completed, and increase our research budget to over 24 million €. We are very excited for these brand new R&I initiatives, a preview of which you can get below, and look forward to working with our partners to transform industry with the power of AI.

DEXPLORE

DEXPLORE seeks to revolutionise mineral exploration in Europe by developing innovative approaches to counter declining ore deposit discovery rates, focusing on deep-seated deposits critical for the economy's decarbonisation. The project emphasises engaging the general public and stakeholders, combining innovation at various levels, and utilising cutting-edge tools and technologies. Targeting essential materials across extensive geological terrains, DEXPLORE proposes a holistic innovation package, integrating UAV-assisted in-field mineral detection, advanced Earth Observation methods, and novel deep-land geophysics techniques to reach at least 600 m depth.

The initiative outlines the development of updated ore models, improving exploration technologies, and providing a visualisation platform. This platform will integrate geological, remote sensing, and geophysical data to enhance access to information about EU potential in critical raw materials, while increasing public awareness. DEXPLORE also aims to strengthen cooperation with strategic partner countries, establishing a robust Advisory Board and fostering collaboration with other EU initiatives for joint activities and result sharing.

DEXPLORE represents a collaborative effort to advance mineral exploration, contribute to sustainable sourcing of critical raw materials, and ensure EU's open strategic autonomy.

-

We will determine technical specifications for the software platform and a cloud-based infrastructure, ensuring compatibility with diverse data types and sources. Essential aspects like data ingestion protocols, storage solutions and security measures will be outlined. We will design and implement a robust and secure infrastructure for on-demand data distribution, utilizing established industry tools and frameworks. DEXPLORE will transform data from various devices and components into suitable formats and transmitting them to real-time and near real-time pipelines, through middleware.

We are also in charge of the visualisation dashboard and the UI, catering diverse user needs and preferences and making the user's interaction easier with complex data. We are aiming for an intuitive, responsive, and visually appealing UI with advanced visualization techniques, like 3D accelerated maps by Xcalibur, graphs and charts for data exploration and analysis, while ensuring robust and safe data exchange along. Design, development and use of an Augmented Reality (AR) application by ICCS, will be implemented to the platform, improving awareness of the general public and educate them through immersive visualizations. AR tool will be part of the open days to ensure social participation and engagement.

Additionally, we are heavily involved on the exploitation planning and technoeconomic analysis.

PRIM-ROCK

PRIM-ROCK addresses advanced techniques for the pre-processing of the raw material, calcination and roasting processes, that are commonly used in the mineral and cement industries, supplemented by simulations and decision support systems. The project aims to design, develop, and validate innovative and higher resource efficient processes, optimising existing ones and lowering the level of GHG emissions of extractive industries. AI data-driven models will be utilised and a digital twin for each process will be developed. Finally, the consortium will investigate waste reduction and re-utilisation strategies. The PRIM-ROCK solutions will be demonstrated in 3 different ASPIRE sectors, namely Minerals (magnesite, laterite), Cement (limestone) and Non-ferrous metals (sphalerite, chalcopyrite).

-

We are leading the effort of optimization and integration of Digital Twinning processing (DSS & UI), enhancing the resource efficiency of the calcination and roasting processes. The DSS will integrate diverse streams of heterogeneous information from various models (data-driven models, physics-based models or hybrid models). This system will deliver real-time insights and alerts. A prototype of the UI will be designed, tested and refined based on user feedback. The final UI will be developed integrating the data models and the DSS and user acceptance testing will be conducted.

CORE IC is also leading the effort of Virtual scale up and expansion study suggesting configurations within the energy system’s boundary conditions, linking of additional added value technologies, mainly CCUS and synthetic fuel production. A Reinforcement Learning (RL) algorithm will be employed to train the planning model as well as Black-box models

Finally, we are leading the 3-phased dissemination and communication activities. The early phase will be dedicated to raising awareness among the target groups and will include the brand and visual identity of PRIM-ROCK, with Dissemination activities targetingboth the academic and industry professional communities, through online events like webinars, congresses, etc. The middle phase will be dedicated to growing and consolidating awareness, informing stakeholders and groups about technological breakthroughs and business benefits. The final phase will ensure the long-term impact within targeted communities.

ALCHEMHY

ALCHEMHY aims to develop a set of innovative electrified processes to produce platform chemicals, particularly ammonia, and methanol and a Plasma-Catalytic Hydrogenation process (PCH). To this end, processes configuration will be optimised and novel materials and catalysts compatible with the electric input will be developed, optimising their performance, ramp-up times and enabling milder conditions. This will support the intensification and downscaling of the ammonia and methanol production, facilitating decentralised production integrated with downstream processes and renewable energy generation. The project will contribute to the development of a sustainable chemical industry, by decarbonising the production of both chemicals, supporting the creation of green jobs and improving the competitiveness of European industries, while contributing to a more resilient and secure energy system for the EU, reducing its dependence on imported fossil fuels.

-

CORE Group is leading the development of AI-based data-driven models of the methanol and and ammonia production processes and their combination with the ROMs produced, in order to develop the Hybrid Digital Twin of each of these projects. Data-driven models will consume the available data from the lab scale facilities. Moreover, exploitation of the generated data will provide further insights and information that can attempt to correlate any process parameters with the relevant molecular dynamics properties and interactions of the involved products, optimising the manufacturing parameters and detecting any potential anomalous behaviour of the involved assets. The investigation of Physics-Informed models can be performed for validating the performance of the generated ROMs.

Additionaly, we are responsible for ALCHEMY's Exploitation Plan and IPR management, which involves a three-phase process of analysing results, defining exploitation routes, and developing a post-project roadmap to ensure effective commercialisation and industry impact. The plan includes tailored business models, market size and competition analysis, and a SWOT analysis to address customer needs and validate the value proposition of ALCHEMY's KERs

StreamSTEP

StreamSTEP is a collaborative initiative by 31 organisations across the EU, Switzerland, and the UK, aimed at enhancing heating energy management in industrial processes. The project focuses on waste heat recovery across a wide temperature range using innovative heat exchanger prototypes and high-temperature heat pumps. Advanced manufacturing techniques and novel material alloys will enable these innovations, which will be demonstrated in five sectors: non-ferrous metals, ceramics, minerals, plastics, and refining. Integral to the project is a holistic process digital twinning pipeline, providing infrastructure for optimization agents to manage energy balance, storage, GHG avoidance, and data-driven LCA, ultimately recovering and reusing 50%-90% of waste heat with a payback period of less than three years, while boosting productivity and energy flexibility.

-

CORE IC is responsible for the development and integration of the project's technical components. This includes creating the data architecture and middleware for the digital infrastructure, integrating smart IoT components, and developing hybrid process digital twins. Additionally, CORE leads the effort to expand the Energy Management System (EMS), implementing advanced techniques like machine learning and deep neural networks to optimise industrial processes and energy management .

CORE IC will also be handling the project's communication and leading on the exploitation strategy, with Exploitation Routes (technical and commercial) for KERs, considering IPRs, ensuring that project results are effectively communicated and positioned for market uptake, maximising the impact and commercial potential of the innovations developed.

OPTIMINER

The OPTIMINER project addresses Europe's challenge of efficiently and sustainably recovering Critical Raw Materials (CRMs) from complex and low-grade ores. It aims to reduce Europe's heavy reliance on CRM imports by innovating in recovery methods and promoting sustainable mining practices. Key components include advanced technologies like an AI-enabled CRM Recovery Selector and a digital platform (DIGIMINER) for smart monitoring and control. ECOMINER focuses on sustainability through energy and water optimization, waste valorisation, and toxicity management. DEMOMINER showcases pilot lines across multiple countries, demonstrating practical applications, while GLOBEMINER promotes market awareness and strategic EU-Chile cooperation in CRM recovery.

-

CORE IC is leading the effort for the technical plan of each use case, including technical specifications and technological experties (AS IS situations, data availability, sensors connectivity, other operating systems). We are also in charge of the CRM Recovery Selector, defining criteria and parameters, developing technology database with a detailed profile of each use case, along with algorithm development with customizable capabilities and a UI design intergating a digital assistant (NPL-based).

The DIGIMINER platform will be built on data-driven Digital Twins, by leveraging sensorial, historical and operational data and proper abstraction and distribution among the data sources. We will design the connections and interactions of Digital Twins, DSS and Virtual Miner, as well as, establish a cloud infrasturucture, featuring hybrid data warehouse. New data from simulation results and experimental data cross corellation will be adjusted to the model. A modular AI-augmented market observatory will be designed forecasting mining market values.

The team of experts at CORE IC will also be leading dissemination and communication, as well as exploitation and innovation management activities, with a heavy focus on awareness about the project's outcomes and their impact, emphasizing sustainable raw materials production.

Theseus

The Theseus project focuses on implementing Industrial-Urban symbiosis (I-US) through Hubs4Circularity (H4C) in Europe, starting with the Athens/Attica region in Greece. This initiative involves municipalities and industries collaborating to manage resources, waste, energy, water, and infrastructure in a sustainable manner. The project aims to establish the first-of-its-kind H4C hub in Greece, leveraging regional needs and digital technologies to develop solutions for water, energy, and materials. These efforts align with EU objectives, aiming for climate neutrality by 2050 and closing resource loops through innovative governance models and stakeholder cooperation. Theseus integrates existing innovations and aims to replicate successful solutions across other EU regions, drawing parallels to the transformative legacy of Theseus in Athenian mythology.

-

CORE Group will work on defining key performance indicators (KPIs) for monitoring impacts across various dimensions, facilitating informed decision-making in subsequent project tasks. The project focuses on coordinating digital plans for pilots and mapping data requirements to finalize a comprehensive data model. CORE Group will also be leading the integration of diverse data sources and ensuring secure and efficient data exchange across all project activities, collaborating closely with partners to implement cost-effective and robust data acquisition measures. Additionally, we are going to design and operate a Predictive Resource Logistics Module (PRLM) within the Hubs4Circularity framework, predicting material and water flows and generating socio-economic and environmental indicators. It aims to identify bottlenecks, business opportunities, and scalability options, with plans for post-project automation. A digital platform will be developed, integrating various modules and services for industrial symbiosis, enabling collaboration and resource tracking, supported by advanced analytics and user feedback for iterative platform optimization. Outputs include detailed reports and functional platform releases.

JOULIA

The JOULIA project aims to develop and demonstrate innovative induction and microwave heating processes for rubber vulcanisation and glue thermal activation in the rubber and plastic sectors, optimising them for flexibility, energy savings, and integration of renewable energy sources. These processes will be refined using digital models and simulations, ensuring adaptability, cost optimization, and compliance with health and safety standards, while predictive maintenance tools support ongoing operation. The project involves 16 partners from 7 EU countries and aims to enhance European industrial resilience, decrease fossil fuel dependence, and improve energy efficiency and sustainability, with potential applications in other sectors like food and ceramics.

-

We are responsible for leading the identification of Funding Sources and Financial Instruments that can support the replication and upscaling of JOULIA innovations. We are also involved in the task of business models development that leverage the project's technological advancements to identify new market opportunities and in the task of the identification of Regulatory and Standardization Barriers that may hinder in the market uptake of JOULIA technologies.

We are involved in exploitation management tasks, contributing to the overall coordination and decision-making processes within the project.

rEUman

The European remanufacturing industry is essential for Europe's sustainable transition due to its energy, material, and functionality savings, along with significant socio-economic benefits like job creation and technological advancement. To enhance competitiveness and future-proof the industry, it is crucial to address barriers such as limited automation, poor human inclusion, and lack of digitalisation.

The rEUman project aims to develop a human-centric remanufacturing approach by improving factory-level regeneration and traceability and ensuring stability in the value-chain, while demonstrating its effectiveness in the automotive, home appliances, and optoelectronics sectors.

-

Our technical role in the rEUman project encompasses the design and development of digital and AI-driven systems that evaluate the condition of returned products through image analysis at collection points, such as workshops or service centers. By assessing the remanufacturability of parts, the system aims to optimize decision-making regarding whether parts should be sent for remanufacturing, considering both technical and economic feasibility. This process is intended to minimize logistics costs and environmental impacts by avoiding the unnecessary transportation of non-remanufacturable parts.

INBLANC

Significant challenges in the building and construction value chain stem from fragmentation and siloing, necessitating a systemic change through lifecycle perspectives to uncover interactions and opportunities. INBLANC aims to establish an open ecosystem focused on building lifecycle data, using low-cost data collection, consolidation in Building Digital Logbooks, and interfacing with EU dataspaces. The project will demonstrate its approach through six diverse demo cases, engage actors across the value chain, and integrate high-value services for energy planning, facility management, and renovation planning, aiming for near-market readiness.

-

CORE IC is responsible for the development of smart energy services tools like the RES Selector and Energy Management System (EMS), which optimise renewable energy source investments and balance system energy consumption and their validation using gap detection and optimization for city-scale identification and remedy recommendation. We are creating new technologies using high-performance computing infrastructure for tasks such as deep learning model development and energy consumption forecasting that support support advanced modeling, simulation, and machine learning applications.

Furthermore, CORE is also leading the communication, dissemination, innovation and exploitation activities.

We are also leading the communication, dissemination, innovation and exploitation activities.

CORE Group launches the Greek Smart Factory

Author: CORE Group Managing Partners

July 17th 2024

CORE Group’s newest endeavor, the Greek Smart Factory, is off to a great start following its launch last month.

The Greek Smart Factory is a platform for manufacturers, tech providers and academia, allowing them to network, innovate, and advance in a real industrial environment.

The CORE Innovation Centre (CORE IC), CORE Group’s research and innovation powerhouse, is dedicated to fostering an innovative industrial ecosystem. Through participating in over 50 Horizon EU projects, with over €24 million in EU funding, and a network of more than 300 partners worldwide, CORE IC and CORE Group have developed an expertise in developing Industry 4.0 solutions for various sectors, including extraction, processing, manufacturing, buildings, infrastructure, and energy systems.

Thanks to this rich know-how, and through its participation in the Twin4Twin project, CORE IC has been funded to create the Greek Smart Factory – a trusted platform for manufacturers and tech providers to network, innovate, and advance on their Industry 4.0 journey.

Announcing the Greek Smart Factory to the world

The official announcement took place during the 5th International Smart Factory Summit in Switzerland. Stefanos Kokkorikos and Nikos Kyriakoulis, CORE Group Founders and Managing Partners –visionaries behind the Greek Smart Factory initiative– were invited, to share their vision with fellow smart factory innovators from across the world. Alongside the Swiss Smart Factory, CORE Group acted as the European representatives to our global network of smart factories.

Following the announcement, a stakeholder workshop took place at the CORE Group central offices in Athens, Greece. The workshop was attended by key professionals and manufacturing decision-makers from Greece and our global network, who showed their trust in the Greek Smart Factory vision and provided feedback on our approach, based on their own success stories and the industry’s active needs from such a ground-breaking initiative.

A trusted platform to network, innovate, and advance

The Greek Smart Factory (GSF), envisioned as a legacy scheme, aims to provide a virtual and physical platform for all the needs of manufacturers and tech providers. This platform will allow key decision-makers to apply the latest and greatest academic innovations in an environment that seamlessly simulates their actual industrial setting. Members will be able to use GSF to find resources and solutions to their daily challenges, through interactive partnerships and through identifying their ideal markets. Our resources will be available for members to innovate, testing new technologies and business models, so they can change their status quo and advance in a safe environment before they make the actual investment.

On top of actual, testing-ground collaborations, we want to offer members a space where they can interact through training sessions, pitching meetings and brainstorming workshops, to collaboratively address their common challenges in an equalitarian way.

Learn more

The Greek Smart Factory is the culmination of a year’s worth of efforts by CORE Group to help people, industries and organisations fulfil their true potential. Offering a platform with unparalleled resources for manufacturers and tech providers, it is set to revolutionise Industry 4.0 initiatives in Greece and abroad.

Be the first to know the latest news about this pioneering endeavor by subscribing to our newsletter, and receive exclusive updates on industry insights, trends, and company news directly in your inbox.

If you would like to express your interest in the Greek Smart Factory directly, you can reach out to Maria Lentoudi.

Maria Lentoudi

External Relations & Events Coordinator

mlentoudi@core-innovation.com

+306978143191

CORE Group at the Energy Efficiency in Manufacturing Conference

Author: Alexandros Patrikios

July 1st 2024

Last month, the CORE Group team attended the Energy Efficiency in Manufacturing Conference as sponsors.

It was a great day full of intriguing discussions on industrial sustainability, with Valia Iliopoulou, Energy and Resource Efficiency Unit Leader at CORE Group, giving a captivating speech to attendees.

Harnessing Industry 4.0 tools

Valia Iliopoulou, Energy and Resource Efficiency Unit Leader at CORE Group, delivered a presentation to the conference audience, showcasing how Industry 4.0 tools can be used to ensure energy efficiency, flexibility and resilience in the manufacturing sector. Valia presented the REPowerEU plan of the European Green Deal and its challenges for manufacturers, drawing from the real life examples of some key projects CORE Group is involved in, like Trineflex, Metawave, and Streamstep.

You can download Valia’s presentation here.

The conference booth

As always, COREbeat, our all-in-one Predictive Maintenance solution, was there for conference attendees stopping by our booth. Visitors got an exclusive look at beatBox, COREbeat’s hardware component, as well as COREbeat’s highly intuitive UI platform. You can find out more information about COREbeat and how it can help you otpimise your industrial operations here.

We also got to offer some insights into our ground-breaking energy efficiency R&I initiatives, with a focus on Trineflex, which is transforming energy-intensive industrial processes through the integration of energy flexibility and the supply of raw materials. You can get a more in-depth look on our Industry 4.0 research projects here.

Stay in touch

A big thank you to the conference organisers for a very intriguing day talking about our joint efforts towards a sustainable manufacturing future.

CORE Group at the Smart Factory Conference

Author: Alexandros Patrikios

June 27th 2024

This year’s Smart Factory Conference took place in late May, and CORE Group was a sponsor for the event.

It is our second time attending, and it was great to join a highly engaged audience of pioneers in the Smart Factory arena.

Building a Smart Factory in Greece

Dr. Nikos Kyriakoulis, Co-Founder and Managing Partner at CORE Group, delivered a captivating presentation to the conference audiences, discussing the Smart Factory market globally. Drawing a comparison to the international market, he made the point that Greece is lagging behind, and showcased ways for the industry to pave the way forward, towards a Greek Smart Factory, together.

If you didn’t make it to the conference, you can watch his presentation below.

The CORE Group showcase

Conference attendees got to take a look at COREbeat, our all-in-one Predictive Maintenance solution. Stopping by our booth, visitors got to interact beatBox, COREbeat’s hardware component, as well as COREbeat’s highly intuitive UI platform. You can find out more information about COREbeat here.

We also got to offer some insights into our ground-breaking research and innovation initiatives, spearheaded by CORE Innovation Centre. The spotlight was on our Twin4Twin project, which digital twins and expertise exchange with our EU partners, as well as ELEXIA, focusing on a cross-sector digitised energy system.

Stay in touch

A big thank you to the conference organisers for a very intriguing day of meeting our Industry 4.0 peers and exchanging views on the future of smart factories.

See you all at the next event!

Nurturing leadership and soft skills at CORE Group

Author: Antigoni Nikolaidi

June 7th 2024

At CORE Group, our mission is to empower people, industries, and organizations to reach their full potential. We believe that continuous self-development and the enhancement of soft skills are crucial to this journey.

Recently, our management team had the opportunity to immerse themselves in a transformative 3-day leadership workshop held at our offices.

Our CORE goal

This workshop, facilitated by the experts at Game Tree, was meticulously designed to align with our CORE company values. At CORE Group, we are committed to a simple yet profound goal: to be better in six months than we are today. This commitment to growth drives us to continually seek new skills and identify areas for improvement.

The workshop

Game Tree, renowned for their expertise in HR training and development, guided our team through an engaging and interactive series of training sessions. These sessions focused on enhancing leadership skills, fostering better communication within teams, and exploring innovative management approaches. Through dynamic games and activities, our managers learned new strategies for effective collaboration and team communication.

The workshop was more than just a training session. We place immense value on our people, and it is vital for us to work cohesively as a team in our day-to-day operations while also striving to achieve our long-term objectives. The right training, coupled with essential soft skills and practical tools, helps us cultivate an interactive and inclusive workspace.

We extend our heartfelt thanks to Game Tree for their exceptional facilitation of the workshop. Their expertise and innovative approach provided our team with a highly informative and enjoyable experience.

At CORE Group, we are dedicated to fostering an environment where continuous improvement and personal development are not just encouraged but celebrated. This workshop is a testament to our commitment to building a brighter, more collaborative future for our team and the industries we serve.

Our CORE team at Beyond Expo

Author: Alexandros Patrikios

April 29th 2024

Beyond Expo took place this past week, and our team couldn’t miss out.

It’s our second time participating at the event, and we were very excited to meet all our industry friends and participate in some very insightful discussions.

Preparing for the event

Before leaving for the event, we were invited by Naftemporiki TV to talk abour CORE Group, our participation in Beyond Expo, and the AI in manufacturing landscape in Greece and beyond. We were very happy for the last minute call, and for getting the chance to reach a wider audience for CORE Group and its partners.

You can watch the brief interview by Dr Nikos Kyriakoulis, Co-Founder and Managing Partner of CORE Group, in the link below.

Engaging with the community

Throughout the three-day event, we had the pleasure of engaging with many attendees stopping by our booth.

The expo was an interesting mix of industry veterans and AI enthusiasts, all of whom were very excited to see our Predictive Maintenance platform, COREbeat, in action. Our showcase included a motor connected to a beatBox, COREbeat’s hardware component, and visitors were allowed to push a nail in the machine and watch COREbeat’s UI platform spot the malfunction in near-real time. COREbeat already counts many pilots, with the ELEXIA project pilot also shown at the event.

Visitors also got to learn more about our Research & Innovation initiatives through the CORE Innovation Centre, with a focus on the pioneering Greek Smart Factory concept of our Twin4Twin project.

Industry Panel Discussions

Our managing partners, Nikos Kyriakoulis and Stefanos Kokkorikos, were invited to participate in two separate panel discussions, discussing the latest developments in machine learning and AI.

Nikos Kyriakoulis took part in a panel discussion hosted by HETiA and SEKEE, talking about innovation in the industry and opportunities specifically for SMEs.

Stefanos Kokkorikos participated in the main conference of the event, introducing CORE Group and talking about the next best in AI. You can watch the discussion here.

As part of our participation in the expo, Stefanos Kokkorikos was also invited to introduce CORE Group to the conference audience through a brief interview. You can watch the video below.

Stay in touch

A big big thank you to everyone who took the time to stop by our booth and say hi!

We look forward to staying in touch, collaborating, and all the exciting things we can achieve, together.

See you all soon!

CORE Group at the 1st Automation & Robotics Expo

Author: Alexandros Patrikios

April 23rd 2024

The 1st Automation & Robotics Expo was held from April 12 to April 14 in Athens, Greece, and the CORE Group team had to be there.

It was an exciting event full of the latest industry innovations in automation, inspiring insights, and some very meaningful connections.

The CORE Group showcase

Visitors stopping by our booth got an exciting first look at COREbeat, our all-in-one Predictive Maintenance solution, through a live demo rig. Our showcase included a motor connected to a beatBox, COREbeat’s hardware component, and visitors were allowed to push a nail in the machine and watch COREbeat’s UI platform spot the malfunction in near-real time. You can find out more information about COREbeat here.

We also got to offer some insights into our ground-breaking research and innovation initiatives, spearheaded by CORE Innovation Centre, with an exclusive first look at the Greek Smart Factory concept which we are working on, alongside our Twin4Twin project consortium. We also got to showcase the great work our Teaming.AI consortium is doing, helping Industry overcome its lack of flexibility, through the development of human-AI collaboration platform.

Engaging with the community

Throughout the expo weekend, our team had the pleasure of engaging with numerous attendees, from industry veterans to eager-eyed newcomers exploring the realm of automation. We exchanged ideas, shared experiences, and discussed the latest trends shaping the industry.

Things look very promising for the automation and robotics community in this first industry event, and we look forward to witnessing where our shared passion for efficiency and innovation will take the industry next.

Keynote speech

On the second day of the expo, Dr. Nikos Kyriakoulis, Co-Founder and Managing Partner at CORE Group, delivered a captivating presentation on the main stage of the expo, addressing the key challenges facing the manufacturing sector in the era of Industry 4.0 and beyond. From the need for decarbonisation, to generating ESG-relevant business value, Dr. Nikos Kyriakoulis offered potential solutions to all high-stakes industry challenges, using the latest evolutions in AI and machine learning technology.

If you didn’t make it to the expo, or missed the presentation, a recording is now available on our YouTube channel. Simply follow the link below.

Stay in touch

We extend our gratitude to everyone who took the time to visit our booth and engage with our team. We look forward to continuing the journey of innovation and collaboration together.

See you all at the next event!

CORE Group contributes to new publication

Author: Dimitris Eleftheriou

6th March 2024

The latest open access book by Springer, titled “Artificial Intelligence in Manufacturing”, includes our work as part of the Teaming.AI consortium.

The Teaming.AI project

Teaming.AI is an Horizon 2020 project which aims to drive industry-wide change in smart manufacturing, through the introduction of higher customisation and personalisation of products and services in AI technologies. The main instrument is the development of an AI-driven Decision Support System, where decisions can be either taken by a human stakeholder or automatically by an AI service.

“Artificial Intelligence in Manufacturing”