News

The CORE news hub

COREbeat has been installed at key Greek industry facilities

Author: Alexandros Patrikios

July 23rd 2024

COREbeat, CORE Group’s flagship predictive maintenance solution, promises to eliminate downtimes through the use of Deep Learning algorithms.

Offering a 360-solution, COREbeat comprises compact hardware, AI-infused software and an intuitive web and mobile UI and has been applied to many production lines across Europe.

Since last month, COREbeat has been installed in two additional industrial facilities in Greece.

The installation at TERNA MAG mines

TERNA MAG is a magnesite and magnesia producer, and a member of GEK TERNA GROUP, one of the leading business groups in Greece. It exploits the world-class magnesite deposits in the northern part of Evia island.

COREbeat was installed at the TERNA MAG mines to assist the maintenance staff with its cutting-edge predictive maintenance capabilities, increasing their machinery’s lifespan and reducing their production’s downtime. The installation is expected to lead to measurable improvements in the near future.

The installation took place as part of the MASTERMINE Project, which aims to assist the EU mining industry in overcoming the challenges of its green & digital transition.

The installation at the EYDAP wastewater treatment plant

EYDAP is the largest company in Greece in the water supply, sewerage and wastewater treatment sector. It covers the needs of more than 40% of the country's population and supplies the region of Attica with high-quality drinking water.

COREbeat is now up and running at EYDAP’s Wastewater Treatment plant in Metamorfosis, in Attica, with a daily capacity of 24 thousand cubic meters of septic sewage and 20 thousand cubic meters of municipal wastewater. EYDAP staff is going to use COREbeat for monitoring purposes, and it will assist the staff in optimising the energy demand levels of the plant.

The pilot installation is part of CORE Group’s work for the Trineflex Project, which is supporting the transformation of energy-intensive industrial processes through the integration of energy flexibility and the supply of raw materials.

Find out more

If you’re interested in COREbeat’s predictive maintenance capabilities, you can visit out dedicated product page, or reach out directly to info@core-beat.com, to see how our team can help you.

Future-proofing a 120-year old marble quarry

COREbeat is digitally transforming Marini Marmi,

a historic marble quarry in the north of Italy.

Future-proofing a 120-year old marble quarry

Author: Alexandros Patrikios

July 5th 2024

Our sustainable future relies on longevity, which can be ensured through the meaningful restoration and modernisation of our historic past. That is the case for Marini Marmi, a historic stone transformation facility in the North of Italy, which has supplied material for a variety of big structures with significant heritage impact all over the World.

COREbeat is helping this historic facility modernise its legacy equipment and machinery, through the use of cutting-edge predictive maintenance algorithms.

The Dig_IT project

CORE Group’s collaboration with Marini Marmi stems from the Dig_IT project, a Horizon 2020-funded project which aims to address the needs of the mining industry, moving forward towards a sustainable use of resources while keeping people and environment at the forefront. The Marini use-case of the Dig_IT project aims to reduce unpredicted downtime contributing to overall productivity optimisation.

Where COREbeat comes in

COREbeat, CORE Group’s flagship predictive maintenance solution, promises to eliminate downtimes through the use of Deep Learning algorithms. Offering a 360-solution, COREbeat comprises compact hardware, AI-infused software and an intuitive web and mobile UI and has been applied to many production lines across Europe. Its capabilities present Marini Marmi with a pivotal next step in the digitalisation of their facilities.

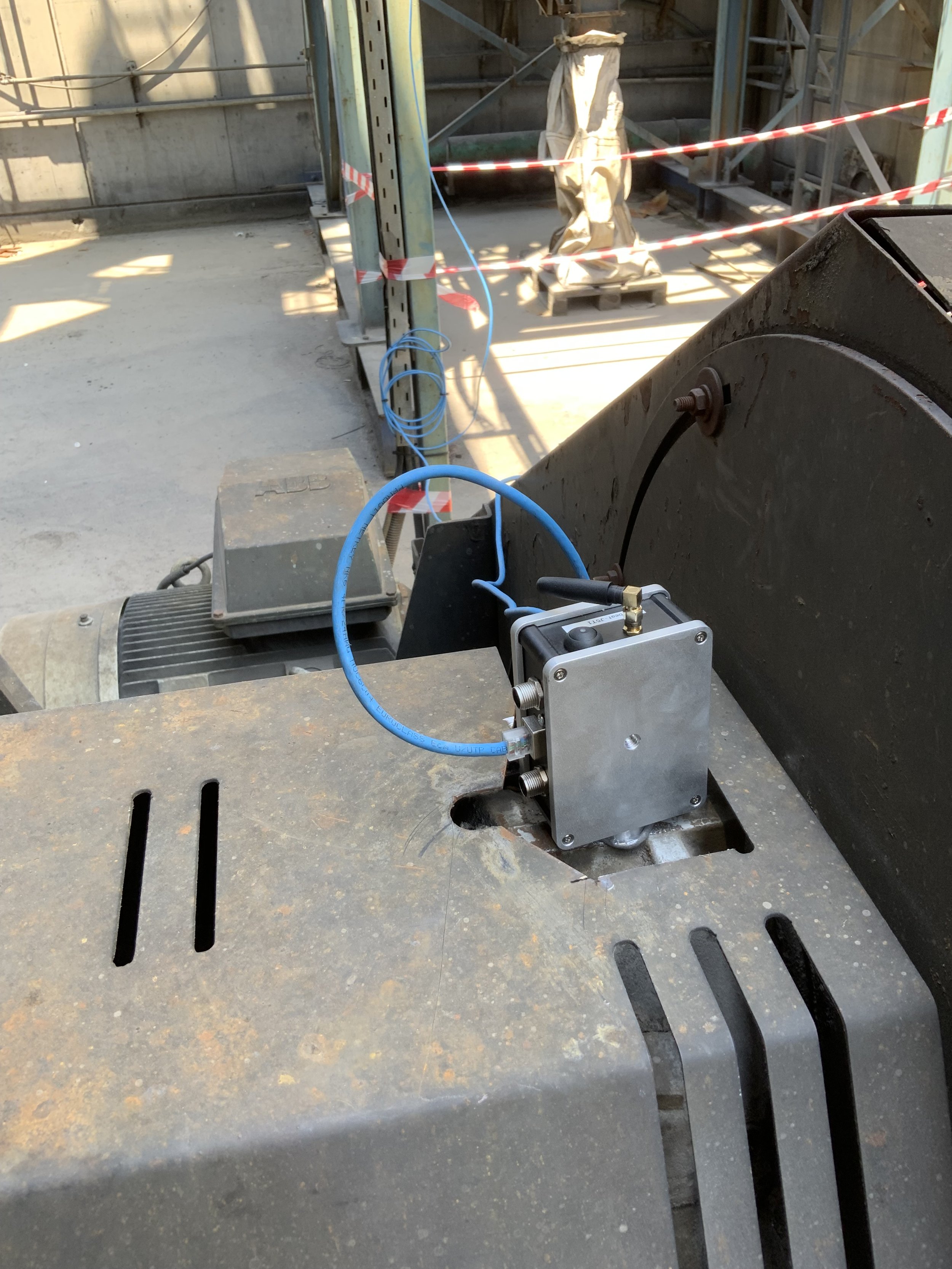

At the Marini Marmi quarry, COREbeat has been installed in different assets of a large-scale marble-cutting engine. Installation took less than 2 hours, and Marini employees could immediately monitor the behavior of their gang saw. In less than 6 weeks, COREbeat’s predictive maintenance capabilities also became available.

When things break down

After the initial installation and training period, the quarry’s employees received a notification, informing them that one of the parts was in critical condition and required immediate attention. In just one week, the part was now in critical condition, with a COREbeat’s health score below 10% indicating that it is time for maintenance. The factory staff scheduled maintenance for the machine 4 days later, and the machine kept working for another 3 days, breaking down within the indicated timeframe. The results were highly positive for COREbeat, but the Marini Marmi staff were faced with delays that might have been prevented.

Find out more

COREbeat is still up and running at Marini Marmi through the Dig_IT project. If you’re interested in finding out more about Dig_IT, you can follow the project’s dedicated page on social media. For all the rest of our 40+ EU research projects, you can find more information on our dedicated webpage.

And if you’re impressed with COREbeat’s predictive maintenance capabilities, you can reach out to info@core-beat.com, and learn how our team can help you.

Transforming Greek manufacturing with COREbeat

CORE Group’s all-in-one predictive maintenance platform

is the go-to solution for EP.AL.ME., the leading Greek manufacturer.

Transforming Greek manufacturing with COREbeat

Author: Alexandros Patrikios

April 11th 2024

COREbeat, CORE Group’s signature product, is here to cover an inherent need of the manufacturing sector – the seamless operation of its production machines.

COREbeat is an all-in-one predictive maintenance solution, encompassing compact hardware, AI-infused software, and a web and mobile UI. COREbeat operates through collecting data using its built-in sensors in real-time, then employing machine learning algorithms to detect behavioural anomalies and and provide early notifications of upcoming failures.

The collaboration

Since last summer, COREbeat has been the driving force behind EP.AL.ME.’s predictive maintenance capabilities.

A subsidiary of MYTILINEOS, EP.AL.ME. is an Aluminium Recycling company that specializes in the processing and sorting of scrap metal and the production (smelting) of recycled Aluminium billets. Their collaboration with CORE Group started as part of the e-CODOMH cluster, whose mission is to upgrade entrepreneurship and create an added value in the Greek construction sector.

Installation

The initial installation of beatBox, COREbeat’s hardware component comprising IoT and Computing Edge devices, takes only 2 hours. Upon installation, employees can monitor the behaviour of their machine right away, through COREbeat’s intuitive User Interface. The predictive maintenance capabilities begin at 4 to 6 weeks, and that’s when COREbeat’s Deep Learning magic comes in at full force. After this initial training period, factory employees receive instant notifications through the app for any anomalies. This way, they know immediately whenever the operational health of a machine asset starts declining.

Below, we have some photos of the EP.AL.ME. installation by the COREbeat team.

How COREbeat helped EP.AL.ME.

EP.AL.ME. came to appreciate COREbeat’s predictive maintenance capabilities soon after installation. Maintenance employees at the facility were notified that one of the fans in the aluminum recycling facility was in critical condition, a few days after scheduled maintenance had already taken place. The factory staff, upon inspection, could not find the source of the malfunction, so they continued operating the fan normally.

In the COREbeat interface, the fan kept appearing to be in critical and worsening condition over the span of 2 weeks, which led the staff to pause its operation for an unscheduled maintenance check. During this check, they found an issue with the motor belt of the fan, which they would have missed without COREbeat. This saved the facility from unexpected downtime, delays in the factory’s production pipeline, and substantial losses due to production delays.

Find out more

COREbeat’s success relies on CORE Group’s long experience in the field of machine learning for manufacturing. With a long list of over 40 EU projects, CORE Group is turning into a household name in AI technologies and their industrial applications.

If you are interested in COREbeat’s predictive maintenance capabilities, you can reach out to our team and share more information on the needs of your manufacturing facility through info@core-beat.com.

From Condition Monitoring to AI-assisted Anomaly Detection: An Industry 4.0 Paradigm

From Condition Monitoring to

AI-assisted Anomaly Detection:

An Industry 4.0 Paradigm

Author: Ioannis Meintanis

12th December 2022

Nowadays, digitalization and automation based on the interconnection of heterogeneous systems have become an integral part of our daily lives.

Behind all these buzzwords the main goal is to use technology and data to increase productivity and efficiency.

Industry is keeping pace with the latest developments by integrating new technologies that can boost its productivity and flexibility exponentially. Manufacturers are adopting new technologies, including Internet of Things (IoT), cloud computing, data analytics and Artificial Intelligence (AI) throughout their production operations.

Condition Monitoring

Condition monitoring (CM) systems are an essential element of this transformation. Predictive maintenance is based on the condition monitoring of the assets to determine whether they will fail during some future period and on taking appropriate actions to prevent the consequences of such failure. Monitoring machines with live sensor data enable humans and intelligent systems to use vast amounts of available data to extract useful information from their production processes, making it possible to reduce costs, keep downtime to a minimum and respond early to possible malfunctions or safety risks.

This of course requires that machines are equipped with instrumentation sensors that collect data and distribute them either locally or via the cloud. Typical sensorial data include temperature, power, torque, pressure, acceleration/vibration signals and more.

This transition is not cost free, but rather require investments on multiple fonts: from provisioning infrastructure material (HW/SW) to training machine operators to perform investigative work based on the new information provided by the CM systems. However, the benefits from adopting condition monitoring systems are multiple:

Planning and implementing predictive maintenance schedules

Reducing maintenance costs through effective maintenance planning

Maximizing production output through outage prevention

Reducing downtime by prolonging equipment life

The traditional way condition monitoring is used, is to observe the monitoring signals and impose hard-coded alarm limits that trigger further maintenance actions. However, such procedure is effective only in simple tasks and requires expertise and good knowledge on the process itself. In complex processes when there are hundreds of sensor measurements, which is often the case in practical applications, it is impossible to assess the health of an asset just by analyzing each measurement on its own.

AI-assisted anomaly detection

This is where AI and deep learning techniques come into play. Unlike a human operator, AI algorithms have no problems analyzing historical datasets for hundreds of sensors over a period of several years. Recent advances in deep learning have shown great performance in modelling complex tasks in various domains.

The basic idea is to utilize an autoencoder network to compress the multidimensional sensor data to a lower dimension representation, which captures the rich interactions between the various signals. It has been observed that as the monitoring machine degrades, the interaction between these measurements is changing which also makes the autoencoder reconstruction error to increase. This can be used as an indicator of machine health which allows us to move from the simple identification of a malfunction to the proactive correction of the underlying problem.

Despite the active research in the field there are still some open challenges related to the low anomaly detection recall rate, the anomaly detection in high-dimensional and/or not-independent data, the noise-resilient anomaly detection and the explainability mechanisms for predictive maintenance (PdM).

COREbeat front-end design and why we chose React

COREbeat front-end design

Why we chose React

Authors: Alexandros Rezkalla, Elias Mantouvalos

14th November 2022

The structure, design, behavior, and content of everything seen on browser are termed as front end. The languages used for front-end development are HTML, CSS and JavaScript. Another name for front end is “client side”. It includes everything that the users experience directly: text, colors, styles, images, graphs, tables, navigation menus etc.

Contrary to front end, users will never interact with the back end directly. The front end is what users see and interact with, while the back end is everything that happens in the background.

The foundations for front-end development are the HTML/ CSS programming languages that produce static pages. As the need for interactivity is more and more in demand, Javascript, a flexible programming language was created and then different libraries and frameworks were developed by the community. A coding library is a collection of standard functionalities – pieces of reusable code such as math functions or others, that are inserted into the code as supplementary functions, whereas frameworks are complete tools that expand the productivity of their base technology (CSS, HTML, JavaScript).

Nowadays, we have a few options when it comes to frameworks. The most used, supported and well documented are React, Angular and Vue. They all do the same thing but in a different manner and with a different syntax. Angular is a full-fledged and opinionated framework that provides all the functionalities out of the box, but with a steep learning curve and increased complexity. Vue is much more flexible and simpler, but it becomes cumbersome for big projects. React has hit a sweet spot among its competitors since it is as simple as it needs to be but with enough rules making it suitable for the development of large-scale projects.

After careful consideration, our framework of choice for COREbeat web application was React. This decision was based on some key advantages:

· Documentation

· Community support

· Third party tools

· Wide selections of libraries

React offers the freedom to developers to choose the tools they need without the extra bundle that Angular comes with. That results in a smaller application size and a better development experience overall. While Vue does something like this, the support for React is much better. Acknowledging the importance of documentation and support, the Facebook team behind React constantly listens to the open-source community to implement new features.

Concluding, our goal is to provide the best user experience possible, while using state of the art technologies. We are always moving forward, constantly looking for new tools to add to our arsenal. We remain agile and open to try and test new, exciting technologies.

COREbeat Technology Pillars, a short intro

A short intro of

COREbeat Technology Pillars

Authors: Georgios Fiotakis, Nikos Monios, Andreas I. Mantelos, Dr Apostolos Chondronasios

26th September 2022

The COREbeat platform brings together cutting-edge technologies to facilitate easy deployment, security, and unparalleled accuracy. But what are those technologies exactly?

Here, we take a closer look at the technologies involved and the outline of COREbeat’s architecture.

The beatBox, which lies at the ‘Edge’, makes up the physical entity of the COREbeat platform. Looking past the controversy about the definition of ‘Edge’ in the Industry 4.0 era, we position the ‘Edge’ at the location/point where data are generated. At this ‘Edge’, we place an efficient computing hardware device (beatBox) able to acquire, process, communicate and even infer predictions. This way, the beatBoxes acquire vibration and temperature signals at the asset level using our own sensing module in sync with our in-house deep learning algorithms. The signals are transformed, packed, and securely transmitted using message broker and data streaming technologies to CORE Innovation’s own cloud platform.

The main goal of COREbeat’s cloud platform is to receive, persist, analyze, and distribute vast amounts of high-volume heterogeneous data in real-time between physically different computation environments, tailored towards Industry 4.0. The COREbeat platform exists within a hybrid computation environment composed of public (AWS, Azure, GCP, etc.), private, and IoT clouds, leveraging different benefits such as scalability, robustness, security and real-time computation.

Following the latest technology trends on cloud computing and orchestration, we are leveraging Kubernetes to construct an environment that allows us to manage and deploy our applications and services seamlessly and securely. The nature of our services demands us to utilize the modern software architecture paradigms. The COREbeat platform is designed based on a microservices architecture (MSA), an event driven architecture (EDA), while data persistence is achieved by a scalable data warehouse solution that will keep your data safe and always available.

To secure a platform such as this, we have considered and deployed machine (M2M) and human-to-machine (H2M) interactions. The COREbeat platform employs certificates, generated and assigned to each device. It uses an asymmetric encryption mechanism to secure end-to-end communication channels, while on a higher level, exposure of our services is secured through reverse proxies. Users and organizations need to be certain that their data are securely stored and distributed across their applications. A key security feature is the authentication & authorization of a platform’s users, which we implemented based on the OAuth 2.0 protocol. Although, there are considerably more practices for security used in different layers and locations throughout our architecture, these will be further explored in a dedicated instalment of our blog soon. Stay tuned!